Product outline

New series with 5kHz high-speed response & noise-insensitive digital output!

●Avalable in 17 different capacities ranging from 0.05 to 10000 N m

●Max rotaitional speed 40000 rpm

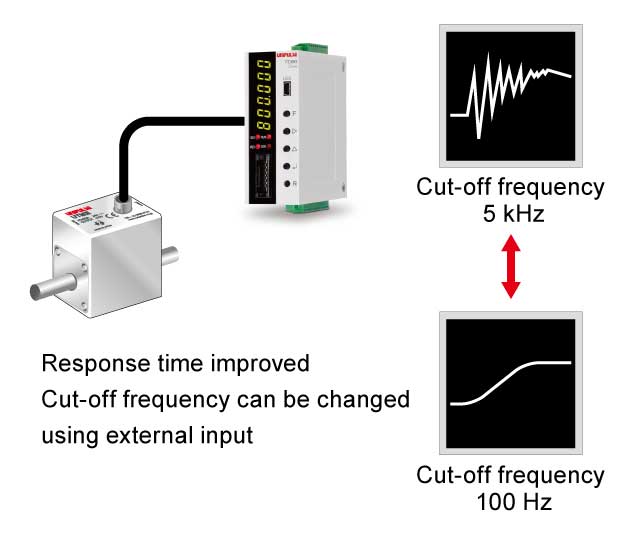

●Analog bandwidth 5 kHz with high-speed sampling rate of 20 kHz.

●Safe overload of 500%

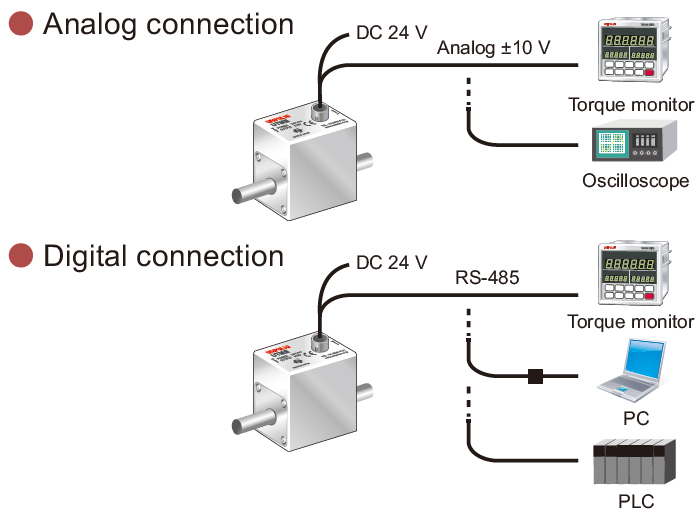

●±10 V of analog output Full Scale

●No need to exchange torque meter! Range switching method cable of measuring two capacities(option)

- 2 N m ↔ 0.1 N m

- 10 N m ↔ 0.5 N m

- 5 N m ↔ 0.25 N m

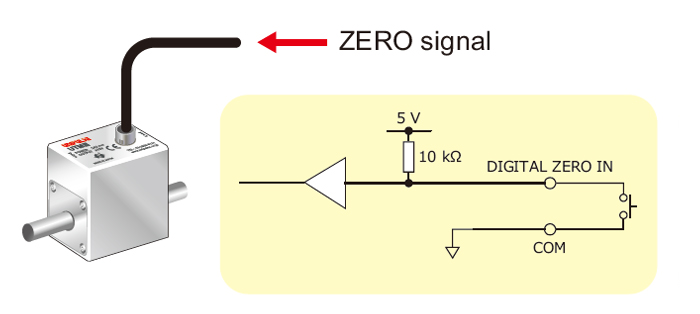

●Digital zero function via external signal

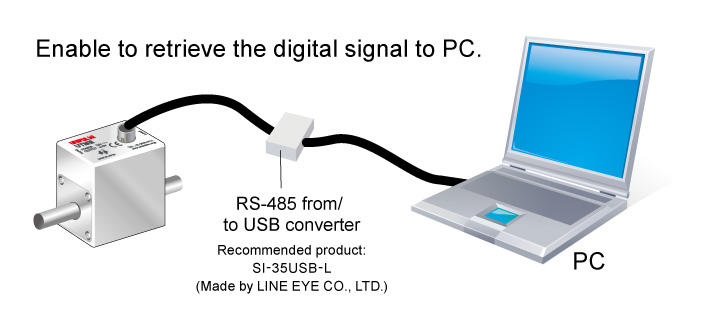

●Digital output via RS-485

●Equipped with pulse output for rotation detection

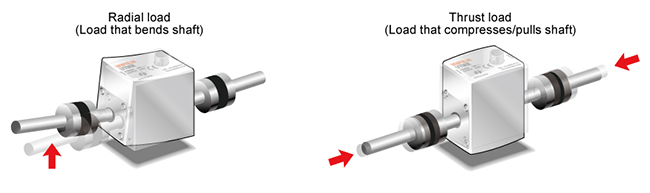

Increased resistance to radial & thrust load

Influences that radial and thrust loads exert on effective accuracy were dramatically reduced.

■Why is load other than torque applied at torque meter?

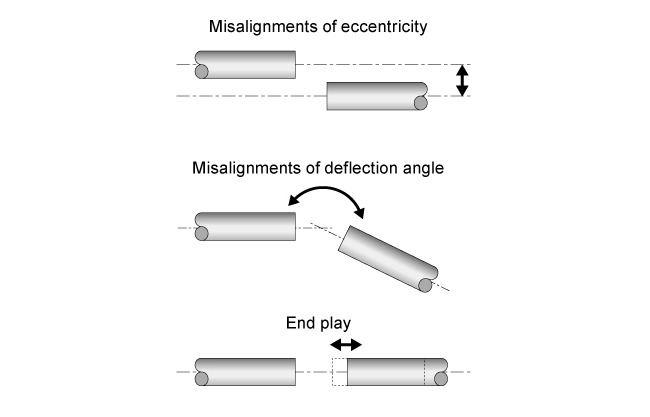

For torque measurement, when interlocking shafts, misalignments on shaft center as illustrated below occur by all means.

The devices that absorb radial and thrust loads caused by such misalignments are couplings. However, even the couplings cannot completely absorb such radial and thrust loads, resulting in an impact on torque measurement.

Major misalignments when mounting shafts

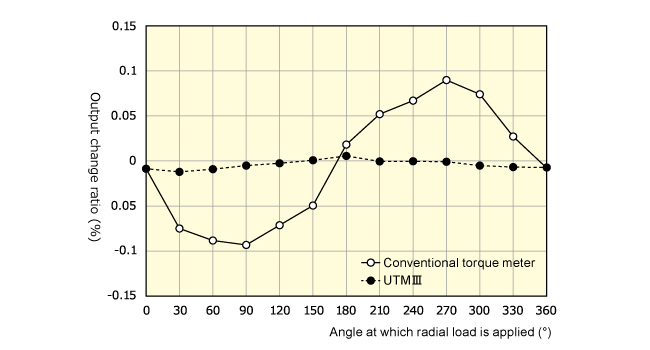

Experimental data

Above illustration shows the output change when one shaft end of UTMⅢ-2Nm is fixed, and 7N radial load is applied at another shaft end through the bearing.

Output changes depending on rotation angle.

While output value changes 0.1% at maximum with conventional torque meter, output value changes less than 0.01% with UTMⅢ.

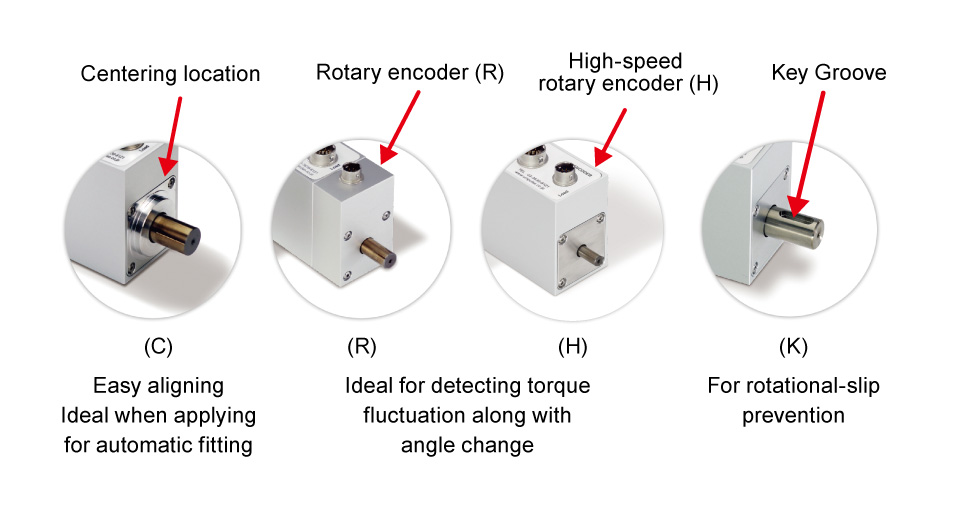

Abundant options available

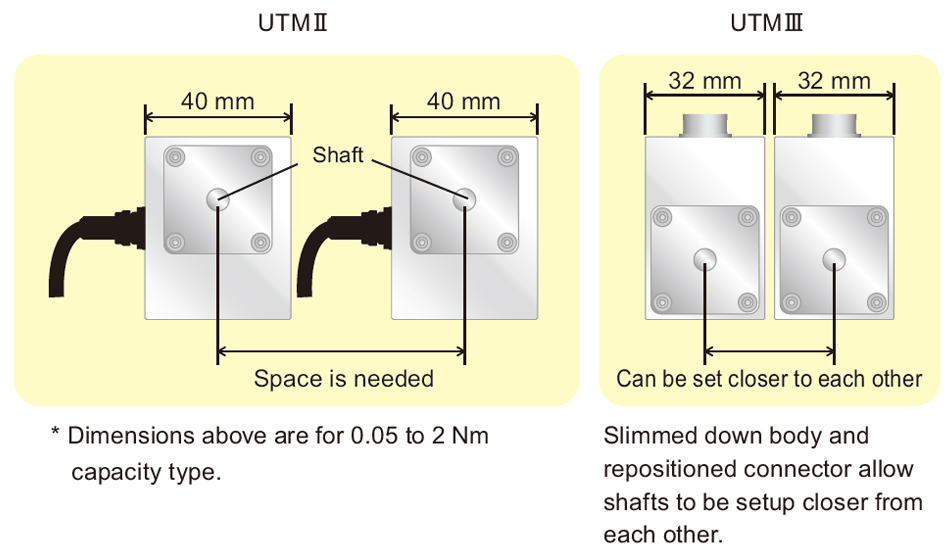

More compact for side-by-side measurement

Added zero correction function with external signal

Frequency bandwidth of 5 kHz, variable filter

Digital output via RS-485

Connection example

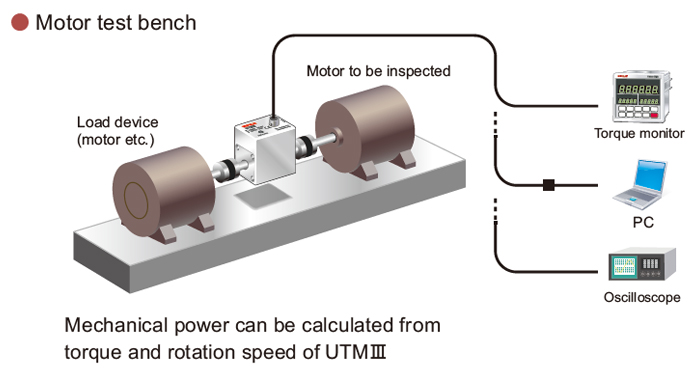

Sample application

Specifications

» Measurement range:±5 N m to ±200 N m

» Measurement range:±500 N m to ±10000 N m

±0.05 N m to ± 2 N m

| Measurement range |

±0.05 N m |

±0.1 N m | ±0.2 N m | ±0.5 N m | ±1 N m | ±2 N m |

|---|---|---|---|---|---|---|

| Power supply | DC 24 V ±15% | |||||

| Consumption current | 100 mA or less | |||||

| Output range | ±10 V DC Load resistance must be more than 5 kΩ | |||||

| Responsivity | 5 kHz | |||||

| Rotation signal |

4 pulses per 1 rotation Open collector Max. ratings 30 V, 10 mA (0.05 to 10 N m model can be changed to 60 pulses in 1 rotation specification. ) |

|||||

| Digital filter | 1 Hz to 1 kHz(Depending on settings) PASS 5 kHz | |||||

| Safe overload | 500% FS | |||||

| Non-linearity | 0.03% FS or less | |||||

| Hysteresis | 0.03% FS or less | |||||

| Repeatability | 0.03% FS or less | |||||

| Operation temp. range |

-10 to +50℃ | |||||

| Temp. effect on ZERO | 0.01% FS/℃ or below | |||||

| Temp. effect on span | 0.01% FS/℃ or below | |||||

| Max. rotation speed | 25000 rpm 0.05 to 10 N m can be changed to a maximum rotation speed of 40000 rpm. |

|||||

| Torsional spring constant |

5.67 N m/rad |

11.57 N m/rad |

26.10 N m/rad |

93.1 N m/rad |

188 N m/rad |

414 N m/rad |

| Maximum torsional angle |

8.81× 10-3 rad (0.505°) |

8.64× 10-3 rad (0.495°) |

7.66× 10-3 rad (0.439°) |

5.37× 10-3 rad (0.308°) |

5.32× 10-3 rad (0.305°) |

4.83× 10-3 rad (0.277°) |

| Inertia moment |

8.48× 10-7 kg m2 |

8.58× 10-7 kg m2 |

8.7× 10-7 kg m2 |

1.46× 10-6 kg m2 |

1.49× 10-6 kg m2 |

1.39× 10-6 kg m2 |

| Ext. dimension (case size/ W×H×D) |

54×49×32 mm | |||||

| Total length | 74 mm | 84 mm | ||||

| Shaft diameter |

φ5 mm | φ8 mm The shaft can be changed to a hollow shaft. |

||||

| Weight | Approx. 140 g | Approx. 160 g | ||||

| Supplied cable |

12-conductor flexible cable (2 m) Cable end: 13 wires → Cable length is switchable to 5 m(Option:UTMⅢ-L5) |

|||||

| Optionally available cable |

CATM351:12-conductor flexible cable (5 m) Cable end: 13 wires CATM312:12-conductor flexible cable (10 m) Cable end: 13 wires |

|||||

| CE marking certification |

2011/65/EU+ (EU)2015/863,2014/30/EU (EN61326-1,EN61326-2-3) | |||||

Permissible shaft end load(N)

The allowable shaft end load (N) for radial and thrust is the value that guarantees that the torque output will not be affected by 0.03% FS or less when these loads are applied.

| Measurement range |

±0.05 N m |

±0.1 N m |

±0.2 N m |

±0.5 N m |

±1 N m |

±2 N m |

|---|---|---|---|---|---|---|

| RadialN | 0.12 N | 0.25 N | 0.3 N | 0.5 N | 1 N | 8 N |

| ThrustN | 3 N | 4 N | 5 N | 6 N | 8 N | 30 N |

| RadialN (R, RC, RK, RCK) |

0.07 N | 0.14 N | 0.17 N | 0.3 N | 0.6 N | 5 N |

| ThrustN (R, RC, RK, RCK) |

3 N | 4 N | 5 N | 6 N | 8 N | 30 N |

Option

| Measurement range |

±0.05 N m |

±0.1 N m |

±0.2 N m |

±0.5 N m |

±1 N m |

±2 N m |

|---|---|---|---|---|---|---|

| Key Groove | ||||||

| Rotary encoder | ○ | ○ | ○ | ○ | ○ | ○ |

| Key groove & Rotary encoder |

||||||

| Centering location |

○ | ○ | ○ | ○ | ○ | ○ |

| Key groove & Centering location |

||||||

| Rotary encoder & Centering location |

○ | ○ | ○ | ○ | ○ | ○ |

| Key groove & Rotary encoder & Centering location |

||||||

| Dual range | ○ |

±5 N m to ±200 N m

| Measurement range |

±5 N m | ±10 N m | ±20 N m | ±50 N m | ±100 N m |

±200 N m |

|---|---|---|---|---|---|---|

| Power supply | DC 24 V ±15% | |||||

| Consumption current | 100 mA or less | 150 mA or less | ||||

| Output range | ±10 V DC Load resistance must be more than 5 kΩ | |||||

| Responsivity | 5 kHz | |||||

| Rotation signal |

4 pulses per 1 rotation Open collector Max. ratings 30 V, 10 mA (0.05 to 10 N m model can be changed to 60 pulses in 1 rotation specification. ) |

|||||

| Digital filter | 1 Hz to 1 kHz(Depending on settings) PASS 5 kHz | |||||

| Safe overload | 500% FS | |||||

| Non-linearity | 0.03% FS or less | |||||

| Hysteresis | 0.03% FS or less | |||||

| Repeatability | 0.03% FS or less | |||||

| Operation temp. range |

-10 to +50℃ | |||||

| Temp. effect on ZERO | 0.01% FS/℃ or below | |||||

| Temp. effect on span | 0.01% FS/℃ or below | |||||

| Max. rotation speed | 25000 rpm 0.05 to 10 N m can be changed to a maximum rotation speed of 40000 rpm. |

20000 rpm | 15000 rpm |

12000 rpm |

||

| Torsional spring constant |

691 N m/rad |

1851 N m/rad |

5386 N m/rad |

8428 N m/rad |

17.3× 103 N m/rad |

41.7× 103 N m/rad |

| Maximum torsional angle |

7.24× 10-3 rad (0.415°) |

5.40× 10-3 rad (0.310°) |

3.71× 10-3 rad (0.213°) |

5.93× 10-3 rad (0.340°) |

5.78× 10-3 rad (0.331°) |

4.79× 10-3 rad (0.275°) |

| Inertia moment |

3.56× 10-6 kg m2 |

3.66× 10-6 kg m2 |

2.59× 10-5 kg m2 |

2.66× 10-5 kg m2 |

6.59× 10-5 kg m2 |

1.40× 10-4 kg m2 |

| Ext. dimension (case size/ W×H×D) |

57×54×37 mm | 70×63×47 mm | 67× 63.5× 56 mm |

67×68× 61 mm |

||

| Total length | 97 mm | 150 mm |

170 mm |

177 mm | 187 mm | |

| Shaft diameter |

φ12 mm The shaft can be changed to a hollow shaft. |

φ20 mm | φ25 mm | φ30 mm | ||

| Weight | Approx. 250 g | Approx. 670 g | Approx. 1.1 kg |

Approx. 1.4 kg |

||

| Supplied cable |

12-conductor flexible cable (2 m) Cable end: 13 wires → Cable length is switchable to 5 m(Option:UTMⅢ-L5) |

|||||

| Optionally available cable |

CATM351:12-conductor flexible cable (5 m) Cable end: 13 wires CATM312:12-conductor flexible cable (10 m) Cable end: 13 wires |

|||||

| CE marking certification |

2011/65/EU+ (EU)2015/863,2014/30/EU (EN61326-1,EN61326-2-3) | |||||

Permissible shaft end load(N)

The allowable shaft end load (N) for radial and thrust is the value that guarantees that the torque output will not be affected by 0.03% FS or less when these loads are applied.

| Measurement range |

±5 N m | ±10 N m | ±20 N m | ±50 N m | ±100 N m |

±200 N m |

|---|---|---|---|---|---|---|

| RadialN | 15 N | 20 N | 23 N | 60 N | 90 N | 160 N |

| ThrustN | 40 N | 100 N | 360 N | 400 N | 500 N | 800 N |

| RadialN (R, RC, RK, RCK) |

7 N | 13 N | 20 N | 25 N | 60 N | 100 N |

| ThrustN (R, RC, RK, RCK) |

40 N | 100 N | 360 N | 400 N | 500 N | 800 N |

Option

| Measurement range |

±5 N m |

±10 N m |

±20 N m |

±50 N m |

±100 N m |

±200 N m |

|---|---|---|---|---|---|---|

| Key Groove | ○ | ○ | ○ | ○ | ○ | ○ |

| Rotary encoder | ○ | ○ | ○ | ○ | ○ | ○ |

| Key groove & Rotary encoder |

○ | ○ | ○ | ○ | ○ | ○ |

| Centering location |

○ | ○ | ○ | ○ | ○ | ○ |

| Key groove & Centering location |

○ | ○ | ○ | ○ | ||

| Rotary encoder & Centering location |

○ | ○ | ○ | ○ | ○ | ○ |

| Key groove & Rotary encoder & Centering location |

○ | ○ | ○ | ○ | ||

| Dual range | ○ | ○ |

±500 N m to ±10000 N m

| Measurement range |

±500 N m |

±1000 N m |

±2000 N m |

±5000 N m |

±10000 N m |

|---|---|---|---|---|---|

| Power supply | DC 24 V ±15% | ||||

| Consumption current | 150 mA or less |

180 mA or less | 210 mA or less | ||

| Output range | ±10 V DC Load resistance must be more than 5 kΩ | ||||

| Responsivity | 5 kHz | ||||

| Rotation signal |

4 pulses per 1 rotation *1 Open collector Max. ratings 30 V, 10 mA |

||||

| Digital filter | 1 Hz to 1 kHz(Depending on settings) PASS 5 kHz | ||||

| Safe overload | 500% FS | ||||

| Non-linearity | 0.03% FS or less | ||||

| Hysteresis | 0.03% FS or less | ||||

| Repeatability | 0.03% FS or less | ||||

| Operation temp. range |

-10 to +50℃ | ||||

| Temp. effect on ZERO | 0.01% FS/℃ or below | ||||

| Temp. effect on span | 0.01% FS/℃ or below | ||||

| Max. rotation speed | 10000 rpm |

7000 rpm | 6000 rpm | 5000 rpm | 4000 rpm |

| Torsional spring constant |

117×103 N m/rad |

377×103 N m/rad |

717×103 N m/rad |

1649×103 N m/rad |

3255×103 N m/rad |

| Maximum torsional angle |

4.28× 10-3 rad (0.246°) |

2.65× 10-3 rad (0.152°) |

2.79× 10-3 rad (0.160°) |

3.03× 10-3 rad (0.174°) |

3.07× 10-3 rad (0.176°) |

| Inertia moment |

4.70× 10-4 kg m2 |

2.90× 10-3 kg m2 |

5.89× 10-3 kg m2 |

2.01× 10-2 kg m2 |

5.16× 10-2 kg m2 |

| Ext. dimension (case size/ W×H×D) |

67×78× 71 mm |

86×103× 98 mm |

86×119× 111 mm |

97×141× 137 mm |

103×166× 162 mm |

| Total length | 217 mm | 286 mm | 306 mm | 387 mm | 447 mm |

| Shaft diameter |

φ40 mm | φ60 mm | φ70 mm | φ90 mm | φ110 mm |

| Weight | Approx. 2.6 kg |

Approx. 7.4 kg |

Approx. 10.6 kg |

Approx. 21.7 kg |

Approx. 36.2 kg |

| Supplied cable |

12-conductor flexible cable (2 m) Cable end: 13 wires → Cable length is switchable to 5 m(Option:UTMⅢ-L5) |

||||

| Optionally available cable |

CATM351:12-conductor flexible cable (5 m) Cable end: 13 wires CATM312:12-conductor flexible cable (10 m) Cable end: 13 wires |

||||

| CE marking certification |

2011/65/EU+ (EU)2015/863,2014/30/EU (EN61326-1,EN61326-2-3) | ||||

Permissible shaft end load(N)

The allowable shaft end load (N) for radial and thrust is the value that guarantees that the torque output will not be affected by 0.03% FS or less when these loads are applied.

| Measurement range |

±500 N m |

±1000 N m |

±2000 N m |

±5000 N m |

±10000 N m |

|---|---|---|---|---|---|

| RadialN | 300 N | 400 N | 500 N | 1000 N | 1200 N |

| ThrustN | 1800 N | 3000 N | 4500 N | 7000 N | 11000 N |

| RadialN (R, RC, RK, RCK) |

200 N | – | – | – | – |

| ThrustN (R, RC, RK, RCK) |

1800 N | – | – | – | – |

Option

| Measurement range |

±500 N m |

±1000 N m |

±2000 N m |

±5000 N m |

±10000 N m |

|

|---|---|---|---|---|---|---|

| Key Groove | ○ | ○ | ○ | ○ | ○ | |

| Rotary encoder | ○ | |||||

| Key groove & Rotary encoder |

○ | |||||

| Centering location |

○ | |||||

| Key groove & Centering location |

○ | |||||

| Rotary encoder & Centering location |

○ | |||||

| Key groove & Rotary encoder & Centering location |

○ | |||||

| Dual range |

Download

|

Product catalogue(PDF)

|

⇒Download Page | |

|---|---|---|

|

Operation manual(PDF)

|

||

|

External dimension

|

DXF

(ZIP) |

|

|

PDF

|

||

|

Support tools

|

||

|

Software

|

||