What You Want to Know about a Load Cell to Use it for a Long Time

There are a few things you should keep in mind during installation and use of a load cell in order to use it for a long time.

Things to be careful with during installation

When securing a load cell and/or a jig, the load cell may be broken due to overload that is applied by mistake. Especially for a load cell with a very small capacity, it easily exceeds its safe overload even by a fingertip force. By treating it in accordance with the operation manual, the load cell can be mounted safely.

In addition, make sure that the mounted load cell shall be free from looseness. If there is a backlash, predetermined accuracy cannot be gained, but also abnormal vibration and wear may occur. As a result, it may lead to the breakage of the load cell.

If a load cell cable is either being inflected, dragged or impacted by vibration, be sure to fix the cable. Disconnection due to metallic fatigue of internal conducting wire can be prevented. Do mind the bending radius of the cable as well.

Reasons for the failure of load cells mounted normally?

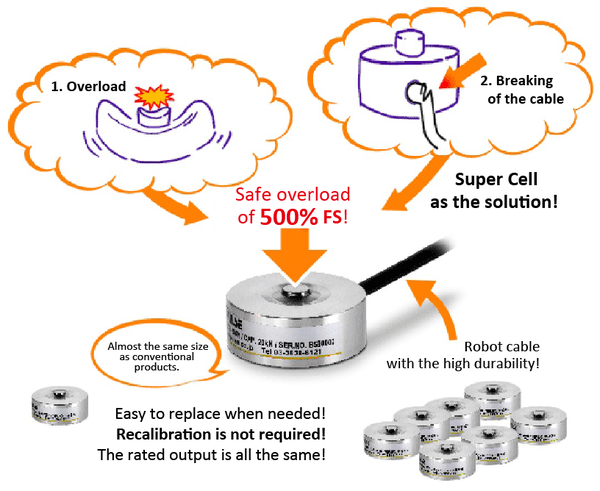

Breaking of a cable

Other than a cable being caught by accident, there are cases such as fatigue breakdown of internal conducting wire due to vibration.

Overload

Even if static load is below the rated capacity, a high frequency vibration may affect a load cell. For example, if a workpiece makes strident noise during an ultrasonic press fitting or a press fitting, a peak load that significantly exceeds the safe overload may occur. If exceeding the safe overload even just for an instant, a load cell will become deteriorated, resulting in decline in quality or defect.

Load button worn away

Wear is unavoidable phenomenon when using a load cell for a long time. A degree of wear varies depending on the use condition. In the meantime, a load cell is capable of withstanding long-term use by smoothing or lubricating the surface of a jig plate (used for pressing a load button at square angle.) In other words, if the surface of the jig plate is coarse and not lubricated, wear goes along quickly.

Internal wire disconnection

Inside a load cell, there are wirings that connect from a strain gage to cables. High-frequency vibrations resonate with resonant frequency of those wirings, possibly resulting in disconnection of the wirings. Please be careful with high-frequency vibrations to load cells.

Characteristics of Metal

A load cell is composed of a metallic elastic body that deforms with applied load and a strain gage that measures a "strain"; the deformation volume of the elastic body.

The diagram above shows a relationship between an elongation (strain) of metal and force.

A metal keeps elongating until certain point but eventually gets fractured. And even before the fracture, if it passes through the point called "Yield point", the metal will not go back to normal shape even after removing a load.

The "Safe overload" listed on the specification sheet means that a metal will not possibly go back to normal shape if it exceeds this load even once.

If the shape does not go back to normal, it cannot be used as a sensor anymore. Therefore, make sure to select a load cell with sufficient margin for capacity.

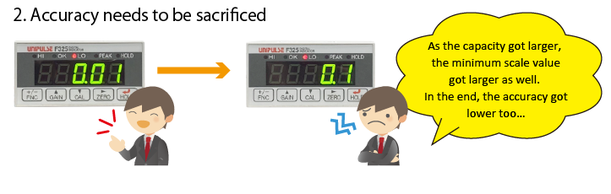

However by doing so, some problems arise such as…

Such problems were resolved by "Super Cell".

- Without scaling up the size of the load cell, improved the safe overload to 500%.

- Used the robot cable that reduced the risk of breakage!

- No individual differences in zero point and full scale, so no calibration needed at a time of replacement.

Super Cell was developed based on the researches for causes of the load cell breakage (mentioned above) with the intention to minimize the downtime of production lines.

In addition to 500% safe overload (120 to 200% with conventional load cells), its architecture is composed of the internal wiring that is not easily resonant with vibration. Robot cable tolerant to flexure is used.

Even if a load cell need a replacement, a misalignment on zero point is adjusted to less than 0.2%R.O. and a sensitivity to less than 0.1%R.O. Thus, no complicated sensitivity adjustment is needed. Just replace the load cell and productions can be resumed.

Super Cell is virtually unbreakable with the safe overload of 500%! Using robot cable with the high durability!

The rated capacity of 50kN with this small body! So small but highly durable!

Super Cell is the ultimate solution of a load cell that can be used for a long time! Full lineup available!

"Super Cell (SCB)" can be ordered at "UG ONLINE USA+Mexico"!

(Only for US 50 states and Mexico residents)