Let's simply build platform scale with accuracy of 0.02%!

Single-point load cell is a load cell that can be used for building weighing systems such as platform scale with only 1 unit.

As errors in the four corners are adjusted from the start, you can build simple weighing system.

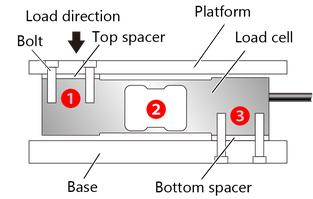

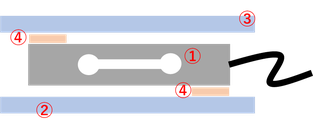

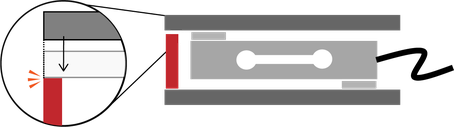

● Structure & installation example of single-point

Place spacers at the positions of (1) & (3).

Strain occurs by applying load at (2) area, and thus load can be measured.

● We actually made it!

1. Preparation

(1) Single-point type load cell

(2) Bottom plate

(3) Top plate

(4) Spacers (2pcs)

(5) M6 countersunk screw (15mm)

* (2) & (3) are identical parts.

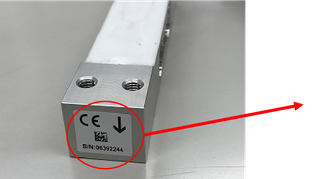

2. Make sure load direction of the load cell.

Assembly image

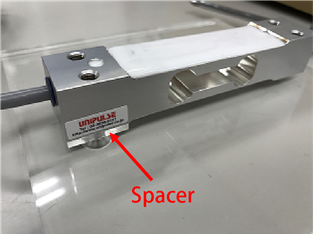

3. Put a spacer and screw the bottom plate.

4. Likewise, put another spacer and screw the top plate.

[Attention!]

When screwing the plates, hold the load cell right by the screws with your hand and tighten the screws.

If applying load to the load cell, there might be a risk of damage due to overload.

5. Complete!

Wipe off dusts if there is any.

Furthermore, do not hold and pull the cable. The cable might be broken.

A stopper will prevent the malfunctions due to overload.

Please consult us for installation ideas.

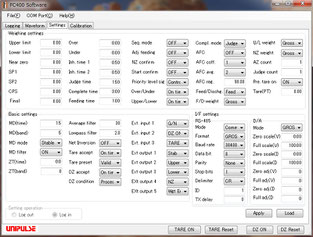

We used FC400-DAC, a weighing indicator with abundant weighting functions.

*FC400-DAC is very convenient as parameters can be instantly set on the dedicated PC software.

Check out the results of calibration & accuracy of this simple weighing system:

While this system is quite simple, weight can be measured in

1 gram for measurement target of 5kg.

We suggest this system for simple weight check such as

omission of assembling workpiece parts.

At UNIPULSE, this platform scale and some other demo units

are available for lending.

Feel free to contact us for more details.

This newsletter is delivered to those who use or consider UNIPULSE products.

If you have any questions or concerns regarding products, CONTACT US from the inquiry form below.