The recent revitalization of the semiconductor industry has increased the demand for many types of sensors.

Load cells, sensors that measure force and weight, are one of them.

Silicone resin is an essential material in the manufacture of load cells. Silicone resins are used in a variety of applications because of their good heat resistance, insulation, and weather resistance. In load cells, silicone resin is used for cable and moisture-proof coating, fixing of wires, and vibration isolation.

However, in the recently booming field of semiconductor manufacturing, siloxane, a gas generated from these silicone resins, causes a variety of problems. In simple terms, siloxane is a polymer consisting of silicone atoms bonded to oxygen and is a very stable substance.

When this adheres to electrical contacts and sticks, it causes contact failure. In addition, adsorption on the lenses of semiconductor lithography equipment or on the surface of silicon wafers can greatly reduce yield rates.

For these reasons, equipment that does not generate siloxane is essential for semiconductor manufacturing sites.

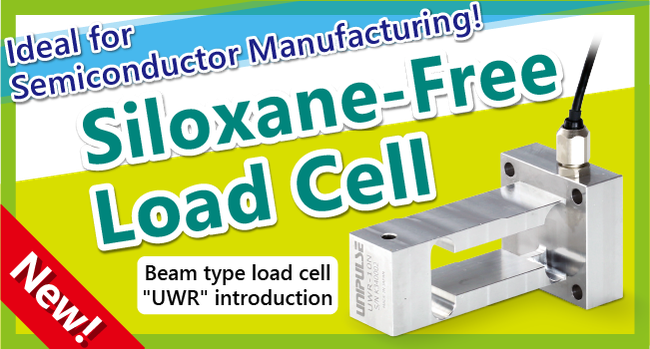

The siloxane-free load cell "UWR" is the solution!

UWR is a beam type load cell. Analysis has confirmed that no siloxane gas is detected, so you can use the product without worries. With a capacity of 10 N, an accuracy of 0.03 %, and a natural frequency of 2.5 kHz, small capacity can be measured with high accuracy and speed.

- Gripping force management of wafer transfer robot

- Management of pushing pressure during wafer polishing

- Load control of chip mounters

- Control of pressure during wire bonding

In addition to the above, it can be used for a variety of applications.

Unipulse's load cells can be custom-ordered in small lots because we manufacture springs and strain gages in-house!

We can provide capacity change, special shape, size change, expansion of operating temperature range, siloxane-free, and so on. Please feel free to contact us.