Product outline

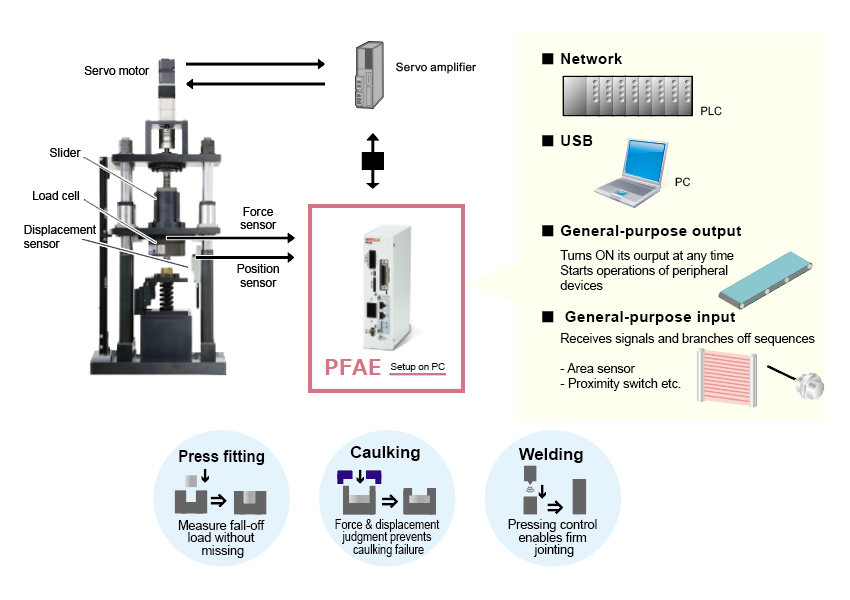

A built-in type press force analyzer including programmable press controller and OK/NOK judgments

● DIN rail mount type; perfect for embedding onto a control panel

● Easy setup on PC

● Just leave process monitoring & control of press machines,

screw tightening machines, testing machines and such to

this 1 device!

● Ultimate solution for motor control!

Anyone can setup sequences easily!

● All-purpose type press force analyzer variety of

judgment functions

● 5000 times/sec. high-speed processing

Sample application

Features

■Retractable neatly with built-in type

As PFAE is DIN-rail mountable, it is possible to keep it in a control panel.

The units can be placed side by side, and are also capable of controlling a number of servo presses at the pressing machine line.

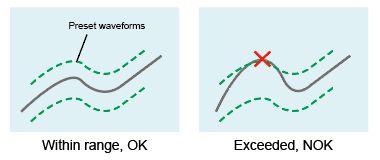

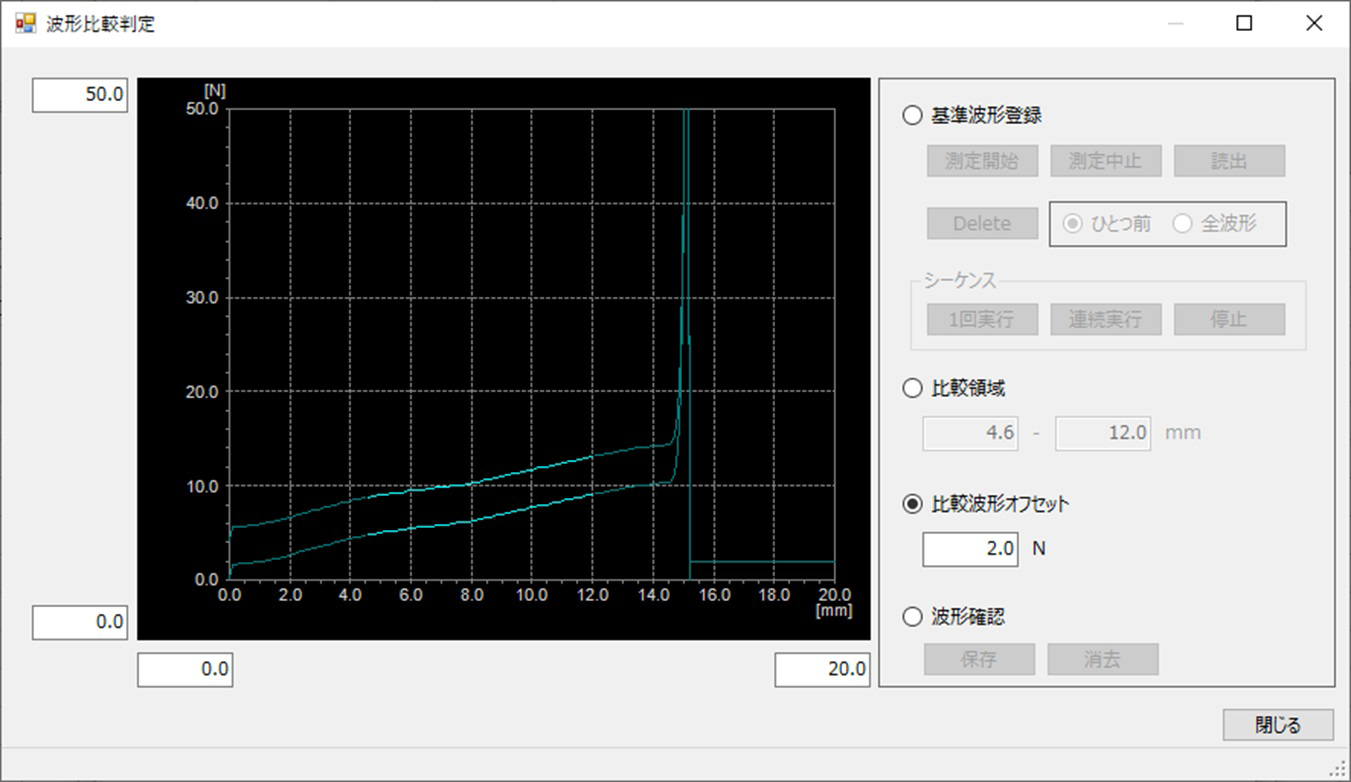

Abundant judgment functions

Constantly compare a preset waveform and a measured waveform.

When any of the point exceeds a preset waveform, it will be judged as NOK.

A preset waveform can be set as desired.

A preset waveform can be set as desired.

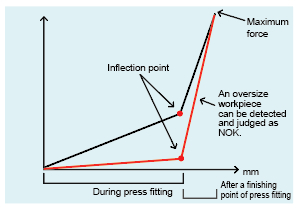

■ Inflection point hold

A hold function ideal for judgment of press fitting.

Automatically detect a force change point just before finishing press fitting.

Easy connection with a host in higher-level

The judgment results and the waveforms can be uploaded to the higher-level host.

As the settings are also manageable from the superordinate remotely, judgments switchover and monitoring and such are easily possible.

Moreover, the judgment results, the waveforms and the setting values can be saved on a SD card too.

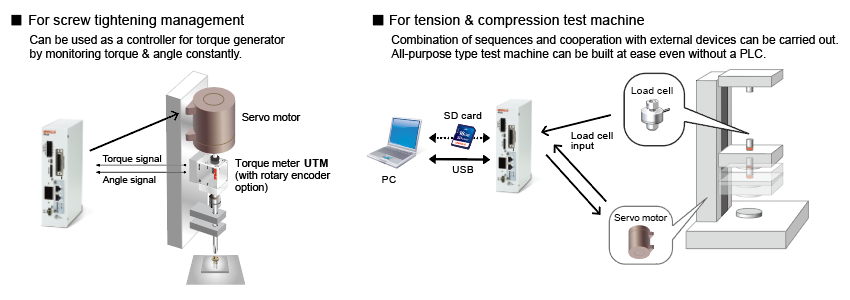

Motor control function

Motor control uses versatile pulse input/output.

Compatible with various motors.

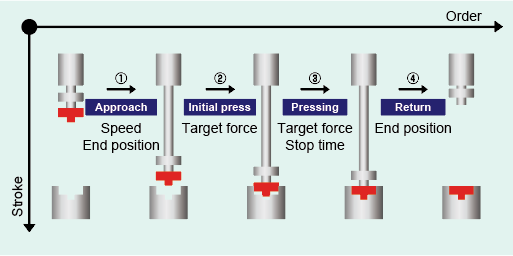

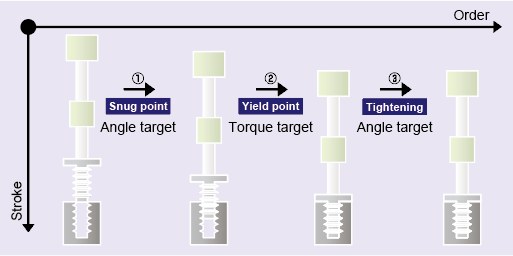

Templates for frequently-used sequences are prepared.

Just enter position, force & speed and the setting is done!

Screw tightening management template compliant to torque method & turning angle method is also available.

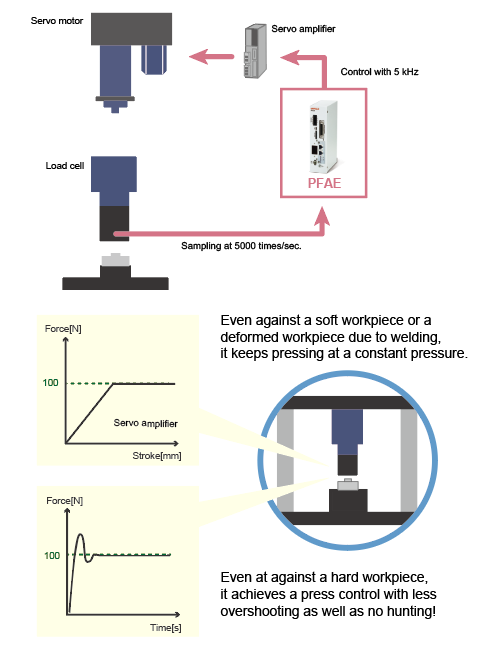

High accuracy & high responsive press control

Retrieves measured value from a load cell with the sampling speed of 5000 times/sec. and performs feedback control with 5 kHz responsiveness.

Compared with conventional press systems, PFAE can achieve higher-accuracy & higher-responsive press control.

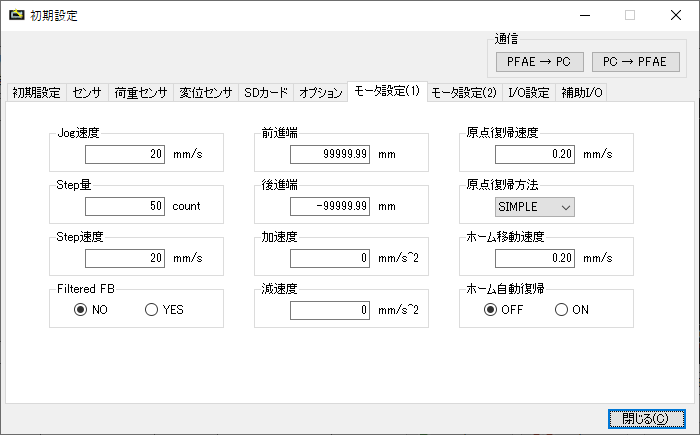

Easy setup on PC

The followings can be performed with a dedicated PC application such as:

– Reading and writing all the setting values

– Configuring judgments while monitoring graphs

– Displaying sequences in a list format

■ Finds setting items quickly

All setting values are configurable on PC.

Being categorized by types, settings can be found intuitively.

■ Configures setting while monitoring a waveform

A judgment can be configured while displaying a waveform.

It is possible to monitor a whole waveform or perform a point judgment.

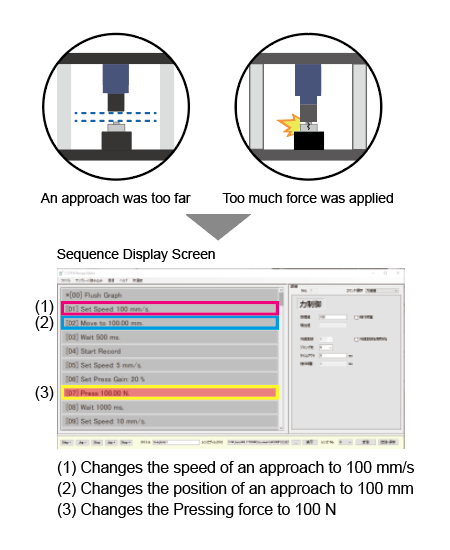

■ Quick recovery even in case of trouble

PFAE is possible to display a sequence in a list format.

Therefore, minor adjustments of “load”, “position” and “speed” are easy to perform.

Specifications

Sensor input|Analog voltage output|Comparison judgment function|External input/output|Motor control|External devices|Interface|General Specification|Attachments|Optional accessories

| Sensor input | |

| Strain gauge input (6-wire type) | |

| Excitation voltage | DC 2.5, 5, 10 V±10% (Depending on settings) Output current: Within 30 mA |

|---|---|

| Signal input range | -2.0 to +2.0 mV/V |

| Accuracy | Non-linearity:Within 0.02% FS±1 digit (at 2.0 mV/V input) Zero drift:0.2 μV/℃ RTI typ. Gain drift:Within 15 ppm/℃ |

| Low-pass filter | Selectable from 2 Hz to 2 kHz (-6 dB/oct.) |

| A/D converter | Speed: 5000 times/sec. Resolution: 24 bit (binary) |

| Voltage input | |

| Signal input range | -10 to +10 V |

| Input impedance | Approx. 1 MΩ or more |

| Accuracy | Non-linearity:Within 0.02% FS±1 digit (at 10 V input) Zero drift:Within 0.2 mV/°C RTI Gain drift:Within 0.01%/℃ |

| Low-pass filter | Selectable from 2 Hz to 2 kHz (-6 dB/oct.) |

| A/D converter | Speed: 5000 times/sec. Resolution: 24 bit (binary) |

| Sensor input for stroke (Pulse input:Line driver) | |

| Max. input frequency | 1 MHz |

| Internal count range | 30 bit |

| Adaptable encoder | Output:Incremental type 2-phase output (A/B-phase signal output) Output stage circuit specification:Line driver (Based on RS-422A) |

| Analog voltage output | |

| Output level | Load cell input Approx. 2 V per 1 mV/V |

|---|---|

| Force resistance | 2 kΩ or more |

| Comparison judgment function | |

| Multi point comparison mode* 16 types can be registered |

Up to 5 point of holds can be compared & judged at the same time Sample, Peak, Bottom, P-P, Relative Minimum, Relative Maximum, Inflection Point, Average, End Displacement |

|---|---|

| Waveform comparison mode* 16 types can be registered |

Compares actual measured waveforms against preset Hi/Lo waveforms. The entire measured waveform will be compared against the preset Hi/Lo and if any of its points exceed the preset waveform, the measured waveform is treated as NOK (Not OK). |

*Comparison mode can be extended up to 256 types. Please ask us for more details.

| External input/output(CC-Link、EtherNet/Ip) | |

| Output signal (16) |

Point judgment (force, displacement)/ Force overload/ Measurement complete/ Waveform comparison/ Force・stroke OK/ CPU OK/ SD card OK/ Timing output 1, 2/ Servo ready/ Motor alarm/ In position/ Brake off/ Torque limit/ Zero speed/ Sequence in progres/ POT/ NOT/ Return origin complete/ None Selectable from the above Output type: As a cyclic communication bit of PLC |

|---|---|

| Input signal (16) |

Force zero/ Stroke adjust/ Measurement start/ Measurement stop/ HOLD 1 to 5/ Reset/ Work selection/ Servo on/ Start sequence/ Stop sequence/ Pulse clear/ Alarm reset/ Forward rotation lock/ Reverse rotation lock/ Home position detect/ Return to home position/ Home position/ JOG+/ JOG-/ STEP+/ STEP-/ None Selectable from the above Input type: As a cyclic communication bit of PLC |

| Motor control | ||

| Compatible servo amplifier | Servo amplifier capable of pulse train input | |

|---|---|---|

| Sequence function | ・Up to 16 control recipe can be registered according to types (Control recipe can be extended up to 256 types. Please ask us for more details.) ・Up to 100 steps of operations can be registered into 1 control recipe ・Full-closed loop force & position control are possible |

|

| Motor interface | Pulse train for position control (A/B phase) Line driver (Based on RS-422A) Max 500 kpulse/sec. |

|

| Motor I/O | Output | Pulse input prohibited/ Accumulated pulse cleared/ Servo on/ Alarm clear/ POT/ NOT |

| Input | Servo ready/ Motor alarm/ In position/ Brake off/ Torque limit/ Origin detection signal | |

| External devices | |

| SD Card | Setting data & waveform can be saved as CSV |

|---|---|

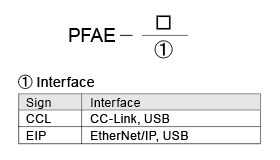

| Interface Only one option can be installed. |

|

| USB | USB interface |

|---|---|

| CCL | CC-Link interface (option) |

| EIP | EtherNet/IP interface (option) |

| General performance | |

| Power supply voltage | DC 24 V (±15%) |

|---|---|

| Power consumption | 6 W typ. |

| Operating conditions | Operation temperature:-10 to +40°C Storage temperature:-20 to +60°C Humidity:85% RH or less (non-condensing) |

| External Dimension | 54(W)×203(H)×136(D)mm (Not including projection) |

| Weight | Approx. 860 g |

| CE marking certification | EMC directive EN61326-1 |

| Attachments | |

| Power connector | 1 |

|---|---|

| Power connector lever | 1 |

| Load cell connector | 1 |

| SD card 16 GByte | 1 |

| Operation manual | 1 |

| Jumper wire | 2 |

| Power cable with ferrule terminals 3 m | 2 |

| USB Cable (A-microB type) 1.2 m | 1 |

| CC-Link connector(when CC-Link option is installed) | 1 |

| Optional accessories | |

| SD16G | SD card 16 GByte (Same as the attachment) |

|---|---|

| SD32G | SD card 32 GByte |

| PFA-CONV-PAN-E | Dedicated terminal block |

| PFA-CONV-MIT-E | Dedicated terminal block |

| PFA-CONV-MIT-ABS-E | Dedicated terminal block |

| PFA-CONV-YAS-E | Dedicated terminal block |

| PFA-CONV-TAM-E | Dedicated terminal block |

| PFA-CONV-SIE-E | Dedicated terminal block |

| CA10-USB | USB Cable (A-microB type) 1.2 m(Same as the attachment) |

| CN71 | CC-Link connector |

Structure of product code

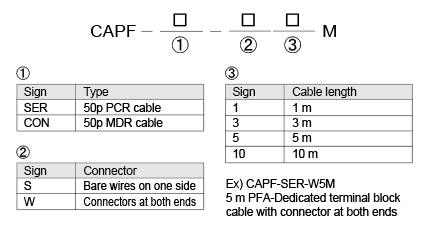

Structure of optional cable

Download

|

Product catalogue(PDF)

|

⇒Download Page | |

|---|---|---|

|

Operation manual(PDF)

|

||

|

External dimension

|

DXF

(ZIP) |

|

|

PDF

|

||

|

Support tools

|

||

|

Software

|

||