Product outline

UTM series have been upgraded to UTMⅡ to better meet the various needs of customers!

Great improvements on the bandwidth (1 kHz), sampling rate (6 kHz), overload rating (500%), and so on have been made, while all great features of the existing model are succeeded.

We will continue to devote ourselves to research and development of unique products. Please feel free to contact us anytime for further information!

●Available in 17 different capacities ranging from 0.05 to 10000 N m.

●Cut-off frequency of 1 kHz with high-speed sampling at 6 kHz.

●Safe overload of 500%

●Power supply DC 24 V

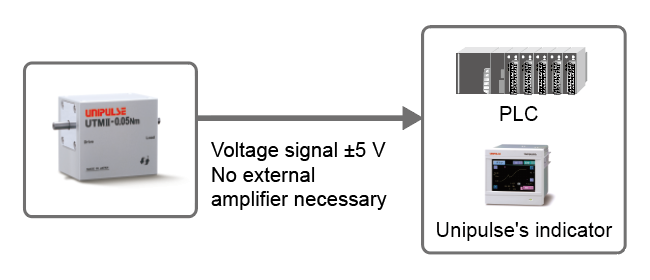

●No external amplification required: ±5 V analog output voltage

●A rotational pulse generating circuit (4 pulses/revolution) is built in as standard.

●Improved noise immunity by adopting an insulated power supply

High accuracy, stability, slip-ring-less, and compact

- Compact and easy to install

The six models (0.05, 0.1, 0.2, 0.5, 1, 2 N m) are particularly compact and light: 54(W)×50(H)×40(D) mm in size, 200 g or less in weight. - High accuracy and stability

1/10000 torque resolution with outstanding zero stability.

UTMⅡ accurately measures tiny torque variations. - Maintenance-free

No slip-ring.

The lifetime of UTMⅡ is mainly determined by the lifetime of bearings. - Max. rotational speed 25000 rpm

0.05 to 10 N m 25000 rpm 20,50 N m 20000 rpm 100 N m 15000 rpm 200 N m 12000 rpm 500 N m 10000 rpm 1000 N m 7000 rpm 2000 N m 6000 rpm 5000 N m 5000 rpm 10000 N m 4000 rpm - Small starting torque

The starting torque of the bearing in the UTMⅡ-0.05Nm is only 0.00001 Nm (0.03% FS).

Actually, the effect of rotating friction can be negligible.

Smart system configuration with no external circuits needed

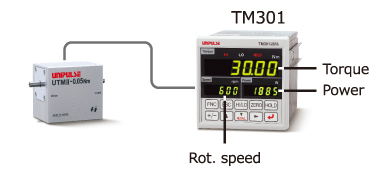

Simultaneous detection of torque and rotating speed

Real-time dynamic measurement is possible from torque and rotation pulse signals.

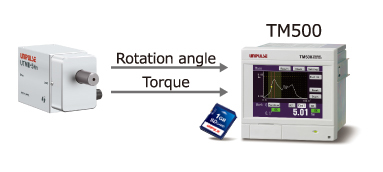

Torque variation against angles is detected

Equipped with an optional rotary encoder to the UTMⅡ, torque and angles are simultaneously monitored.

Specifications

±0.05 N m to ±10 N m|±20 N m to ±10000 N m|Common specifications

| ±0.05 N m to ±10 N m | |||||||||

| Measurement range | ±0.05 N m |

±0.1 N m |

±0.2 N m |

±0.5 N m |

±1 N m |

±2 N m |

±5 N m |

±10 N m |

|

|---|---|---|---|---|---|---|---|---|---|

| Consumption current | 100 mA or less | ||||||||

| Max. rotation speed | 25000 rpm | ||||||||

| Torsional spring constant | 5.67 N m/rad |

11.57 N m/rad |

26.10 N m/rad |

93.1 N m/rad |

188 N m/rad |

414 N m/rad |

691 N m/rad |

1851 N m/rad |

|

| Maximum torsional angle | 8.81× 10-3 rad (0.505°) |

8.64× 10-3 rad (0.495°) |

7.66× 10-3 rad (0.439°) |

5.37× 10-3 rad (0.308°) |

5.32× 10-3 rad (0.305°) |

4.83× 10-3 rad (0.277°) |

7.24× 10-3 rad (0.415°) |

5.40× 10-3 rad (0.310°) |

|

| Inertia moment | 8.77× 10-7 kg m2 |

8.87× 10-7 kg m2 |

8.99× 10-7 kg m2 |

1.49× 10-6 kg m2 |

1.52× 10-6 kg m2 |

1.42× 10-6 kg m2 |

3.56× 10-6 kg m2 |

3.66× 10-6 kg m2 |

|

| Ext. dimension (case size) W×H×D |

54×50×40 mm | 57×55×40 mm | |||||||

| Total length | 74 mm | 84 mm | 97 mm | ||||||

| Shaft diameter | φ5 mm | φ8 mm | φ12 mm | ||||||

| Approx. weight | 160 g | 180 g | 270 g | ||||||

Option

| Measurement range | ±0.05 N m |

±0.1 N m |

±0.2 N m |

±0.5 N m |

±1 N m |

±2 N m |

±5 N m |

±10 N m |

|---|---|---|---|---|---|---|---|---|

| Key groove | ○ | ○ | ||||||

| Rotary encoder | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Key groove & Rotary encoder | ○ | ○ | ||||||

| Square drive | ||||||||

| Square drive & Rotary encoder | ○ |

| ±20 N m to ±10000 N m | |||||||||

| Measurement range | ±20 N m |

±50 N m |

±100 N m |

±200 N m |

±500 N m |

±1000 N m |

±2000 N m |

±5000 N m |

±10000 N m |

|---|---|---|---|---|---|---|---|---|---|

| Consumption current | 150 mA and less | 160 mA and less | |||||||

| Max. rotation speed | 20000 rpm |

15000 rpm | 12000 rpm | 10000 rpm | 7000 rpm |

6000 rpm |

5000 rpm |

4000 rpm |

|

| Torsional spring constant | 5386 N m/rad |

8428 N m/rad |

17.3×103 N m/rad |

41.7×103 N m/rad |

117×103 N m/rad |

377×103 N m/rad |

717×103 N m/rad |

1649×103 N m/rad |

3255×103 N m/rad |

| Maximum torsional angle | 3.71×10-3 rad (0.213°) |

5.93× 10-3 rad (0.340°) |

5.78× 10-3 rad (0.331°) |

4.79× 10-3 rad (0.275°) |

4.28× 10-3 rad (0.246°) |

2.65× 10-3 rad (0.152°) |

2.79× 10-3 rad (0.160°) |

3.03× 10-3 rad (0.174°) |

3.07× 10-3 rad (0.176°) |

| Inertia moment | 2.60× 10-5 kg m2 |

2.67× 10-5 kg m2 |

6.60× 10-5 kg m2 |

1.40× 10-4 kg m2 |

4.70× 10-4 kg m2 |

2.90× 10-3 kg m2 |

5.89× 10-3 kg m2 |

2.01× 10-2 kg m2 |

5.16× 10-2 kg m2 |

| Ext. dimension (case size) W×H×D |

70× 68× 51 mm |

67× 74× 57 mm |

67× 79× 62 mm |

67× 79× 72 mm |

86× 103× 98 mm |

86× 119× 111 mm |

97× 141× 137 mm |

103×166×162 |

|

| Total length | 150 mm | 170 mm | 177 mm | 187 mm | 217 mm | 286 mm | 306 mm | 387 mm | 447 mm |

| Shaft diameter | φ20 mm | φ25 mm | φ30 mm | φ40 mm | φ60 mm | φ70 mm | φ90 mm | φ110 mm | |

| Approx. weight | 700 g | 1.1 kg |

1.5 kg |

2.6 kg |

7.3 kg |

11 kg |

21 kg |

36 kg |

|

Option

| Measurement range | ±20 N m | ±50 N m | ±100 N m | ±200 N m | ±500 N m | ±1000 N m | ±2000 N m | ±5000 N m | ±10000 |

|---|---|---|---|---|---|---|---|---|---|

| Key groove | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Rotary encoder | ○ | ○ | |||||||

| Key groove & Rotary encoder | ○ | ○ | |||||||

| Square drive | ○ | ○ | |||||||

| Square drive & Rotary encoder | ○ | ○ | ○ | ○ |

| Common specifications | |||||||||

| Power supply | DC 24 V ±15% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Output range | ±5 V DC Load resistance must be more than 2 kΩ | ||||||||

| Responsivity | 1 kHz | ||||||||

| Rotation signal | 4 pulses per 1 rotation Open collector Max. ratings 30 V, 10 mA |

||||||||

| Safe overload | 500% FS | ||||||||

| Non-linearity | 0.03% FS or less | ||||||||

| Hysteresis | 0.03% FS or less | ||||||||

| Repeatability | 0.03% FS or less | ||||||||

| Operation temp . range | -10 to +50℃ | ||||||||

| Temp. effect on ZERO | 0.01% FS/℃ or berow | ||||||||

| Temp. effect on span | 0.01% FS/℃ or berow | ||||||||

| Supplied cable | 6-conductor flexible cable (2 m) Cable end: 7 wires → Cable length is switchable to 5 m (Option: UTMⅡ-L5) |

||||||||

| Optionally available cable | CATM51: 6-conductor flexible cable (5 m) Cable end: 7 wires CATM12: 6-conductor flexible cable (10 m) Cable end: 7 wires |

||||||||

| CE marking certification | 2011/65/EU+ (EU)2015/863,2014/30/EU (EN61326-1,EN61326-2-3) | ||||||||

Download

|

Product catalogue(PDF)

|

⇒Download Page | |

|---|---|---|

|

Operation manual(PDF)

|

||

|

External dimension

|

DXF

(ZIP) |

|

|

PDF

|

||

|

Support tools

|

||

|

Software

|

||